MEDICAL AND INSTRUMENTATION

Opportunity to Build Your Future

do you have a machining project we can help with?

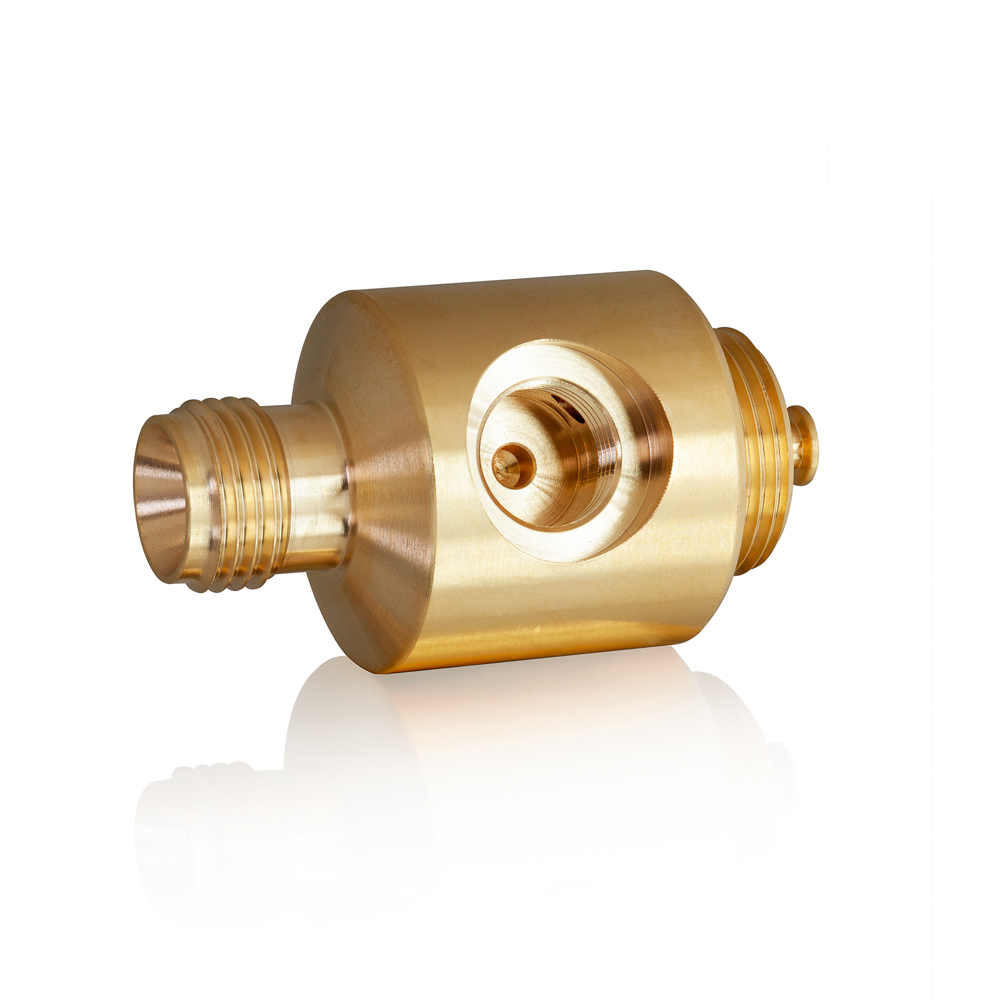

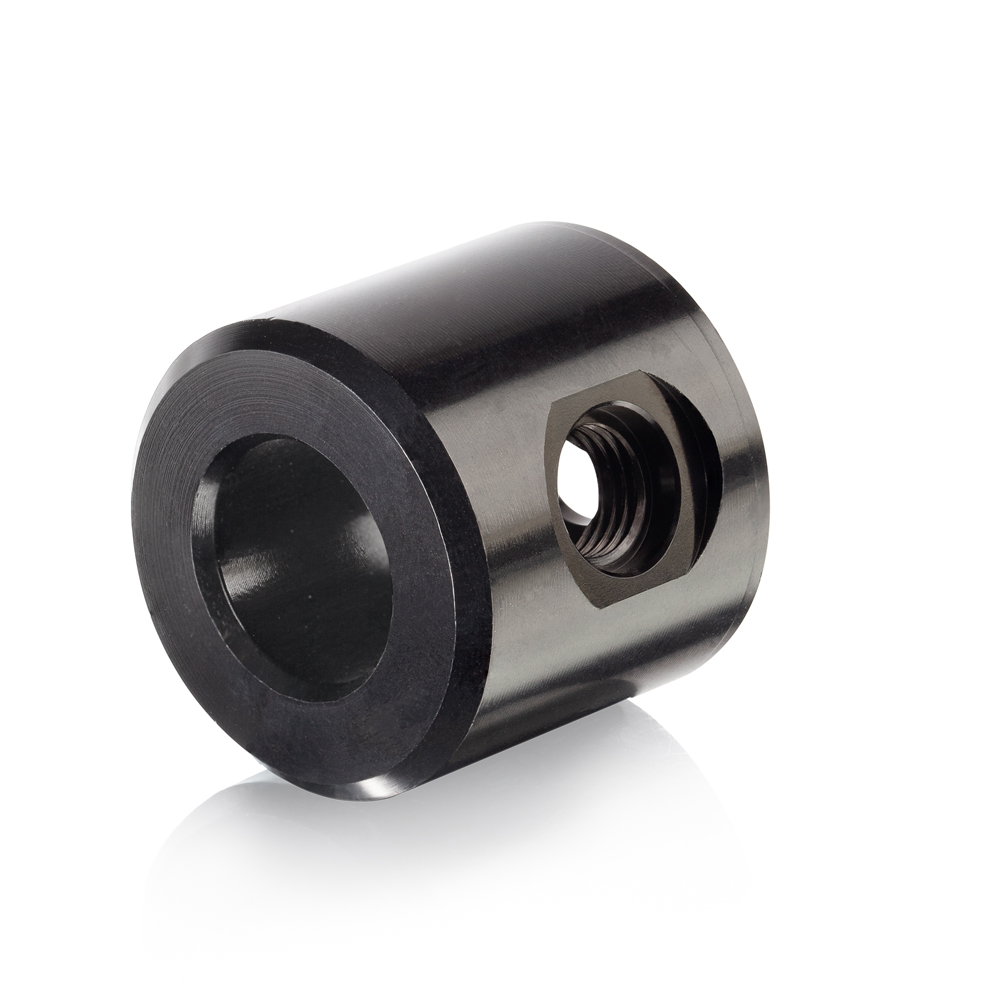

MEDICAL AND INSTRUMENTATION COMPONENTS

We have worked with several Instrumentation and Medical companies over the years to develop manufacturing processes that can compete with our overseas competitors while maintaining the highest level of quality possible. To accomplish this goal our Production and Engineering Departments consistently must think outside the box. For example, we produce a component that not only requires a complex machining center, but due to the nature of the components design is highly acceptable to damage when being handled.

Our “Out of the Box Thinking” lead us to develop a Dry Machining Process that allows us to machine the part complete, and package it at the machine. Over 20+ years we have not had one quality complaint for damaged product. Not only did we improve the quality of the product but reduced their “Total Cost of Acquisition” as well.

Get A Quote Today

We prefer to work with our customers early in the design stage of their projects so that we can make material and process suggestions that will lower our customer’s procurement cost. We will pass on to our customers our machining knowledge of different types of materials such as: BeCu, Stainless Steel, Titanium, Brass, Peek (Plastic), Nylon, Iron Impregnated Teflon, Monel, BO5, and Carbon Steels. Our backgrounds are also very extensive in other manufacturing processes.